China minibagger

1.8 Ton high-end mini excavator introduction

Adopting a well-known domestic engine power system, with strong horsepower, high efficiency and energy saving; The configuration and process have been comprehensively upgraded, and the core hydraulic system adopts imported hydraulic system. The structural parts are precision bored and the surface is shot blasted for rust removal, greatly improving the stability and service life of performance; The unique lateral movement function of the boom is suitable for construction in various narrow boundaries (such as wall roots, pipelines, indoors, etc.).

This best-selling 1.8 ton mini excavator is compact and flexible, with a total working weight of 1800 kilograms and a bucket capacity of 0.03 cubic meters, making it an ideal choice for working in narrow spaces.

In addition, the machine has an independent hydraulic system that provides flexible operation and can be adjusted according to various scenarios to improve construction efficiency.

For more effective communication, you can leave your contact information and we will contact you soon to provide detailed information.

Model | YC-18 |

Engine Brand | Custom |

Power | 18.2KW |

Bucket capacity | 0.03m³ |

Machine size | 3320*1100*2292mm |

Max.dig height | 2100mm |

Track Width | 230 |

Track Length | 1500 |

Max. Digging Radius | 3500 |

Max Digging Depth | 2200 |

Max. Digging Height | 2900 |

Min. Swing Radius | 1467 |

Product details display

Introduction to 1.8-ton high-end micro excavator

1. Equipped with a standard foldable protective frame, it meets the EU Fops/Tops safety certification requirements and provides safety protection for drivers. Folding provides better passability.

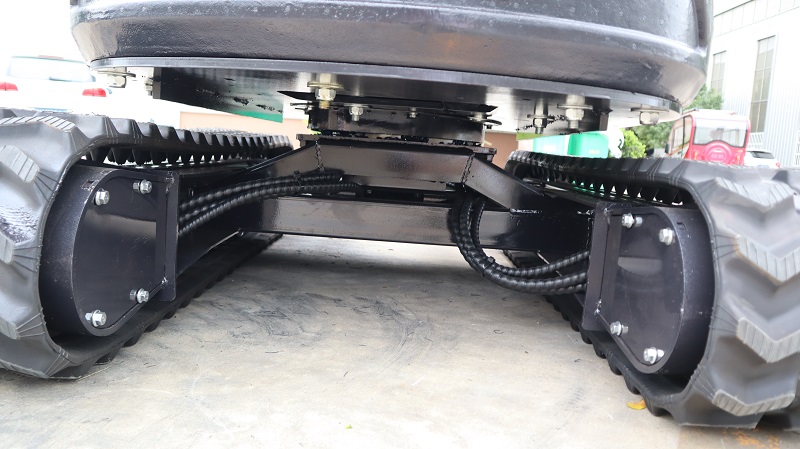

2. By relying on a simple single handle control, the chassis width can be narrowed to accommodate narrow spaces. On the contrary, extending the chassis width can increase stability by 15%, and hydraulic breakers can even be used on small excavators. When expanding and contracting, the YC-18 excavator can smoothly pass through most narrow doorways and enter indoor work smoothly. By relying on a simple rotating shaft, the bulldozer can quickly fold over

3. Each working pipeline adopts a transition connection at the root of the boom, which is easy to maintain and replace. Steel sheaths are used to protect exposed pipelines that are prone to collision or scratching, effectively extending their service life.

4. The reversible engine hood exposes most of the engine area, making maintenance simple and easy. Butter is added in a centralized manner, and external pressure measuring connectors are installed in a centralized manner.

5. Three lifting points, the crane can directly lift and transport, safe and simple.