Best 3.5 ton excavator

The differences between the YC-35U mini excavator and competing products:

1. Differences in plate selection: YC-35U mini excavator is welded from industry standard Q355B manganese plate to ensure the safety of operators.

2. Differences in thickness of excavator plates: our factory selects bottom plate 16-20mm, swing part 20-22mm, large arm 4-6mm and lower plate 8-10mm. The thickness of steel plate meets the standard.

3. Differences of excavator engines: All the engines selected by our factory that can be installed with "replacement" are certified by the brand and can be guaranteed worldwide. If there is no worldwide guarantee, it will be difficult to repair the engine if there is a problem.

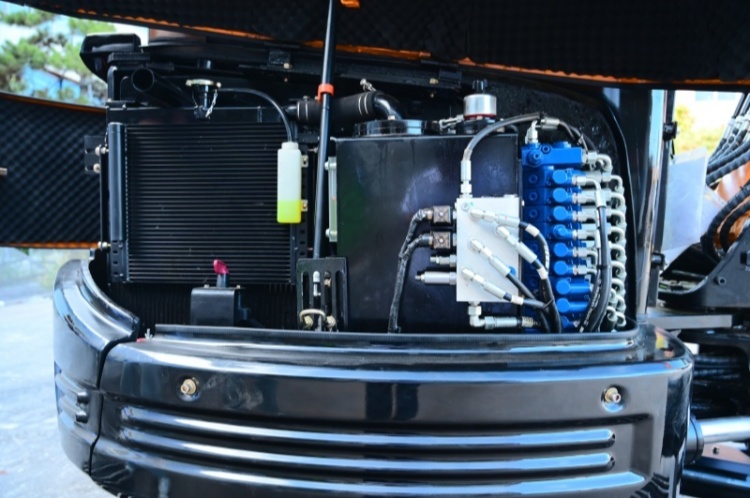

4. Differences of pumps and valves: Our excavator selects the pump valve manufacturers recognized by the industry (Northern, Taifeng, Longgong, Hengli) according to the requirements. It is guaranteed to be strong and durable!

5. Please contact us immediately for the best solution!

The 3.5-ton crawler excavator can be paired with various tools, such as spiral drills, grabs, hydraulic hammers, and narrow buckets, showcasing versatility and high efficiency in a variety of tasks. It is particularly suitable for operations in confined spaces, like orchards where kiwifruit, grapes, oranges, and navel oranges are grown. Additionally, this excavator can handle a range of construction tasks, including excavation and house building.

Model | YC-35U |

Engine Brand | Customizable international brand engines |

Power | 18.2KW |

Bucket capacity | 0.11m³ |

Machine size | 4700*1700*2585mm |

Max.dig height | 4815mm |

Min.swing radius | 2050mm |

Max.dig radius | 5445mm |

Our mini excavator advantages:

1. Our excavator advantages: Our factory is equipped with high-end large boring machines for post-welding processing of excavators. The upper and lower sections, as well as the boom arms, are all processed after welding. Any part that requires installation pins is placed on the large boring machine for simultaneous hole cleaning. This ensures the alignment of the two holes, allowing us to gently insert the pins by hand, thus extending their lifespan. Small factories do not have this capability.

2. Our factory welds the mini excavator boom internally at the same time, and has reinforcing ribs, which can effectively prevent the boom from tearing under improper operation or heavy load by customers, so as to extend the service life of the excavator.

Please don't hesitate to contact us, and our dedicated team will provide you with the optimal solution.