3.5 Ton Small Digger Manufacturer With EPA Euro5 Engine

Our advantages:

1.We are a Chinese excavator manufacturer with over ten years of rich production experience, dedicated to providing customers with high-quality products.

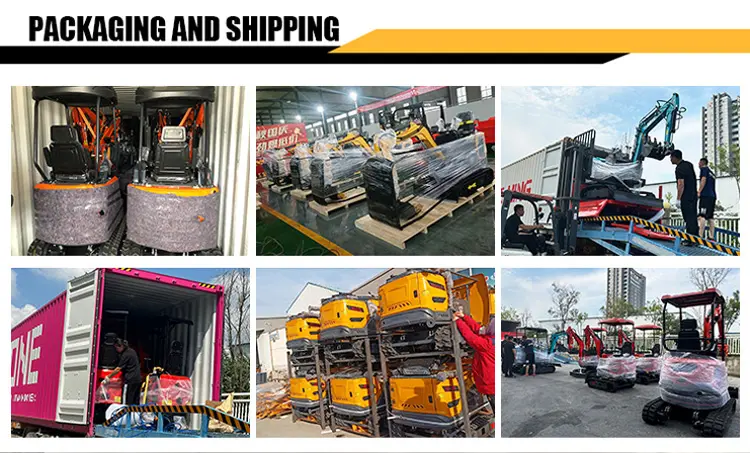

2. All products are in stock and can be quickly arranged for shipment after placing an order to meet your urgent needs.

3. The machine's emissions comply with EU standards and relevant certification documents can be provided to make your use more reassuring.

4. Provide a warranty service of up to 1 to 2 years to ensure worry free use.

5. Each product is equipped with an English operation manual, making it easy for users to quickly get started and use proficiently.

6. Provide video recordings of the transportation process to ensure that the equipment is safely and reliably delivered to your hands.

7. Contact us immediately, and our professional team will tailor the best solution according to your needs!

The YC-35U small excavator is widely used in scenarios such as house decoration, ground repair, cable laying, ditch excavation, farmland operations, and orchard management. It has diverse functions and can perform various operations such as excavation, crushing, ditch cleaning, drilling, and bulldozing to meet the needs of different working conditions.

Model | YC-35U |

Engine Brand | Customized |

Power | 18.2KW |

Bucket capacity | 0.11m³ |

Machine size | 4700*1700*2585mm |

Max.dig height | 4815mm |

Min.swing radius | 2050mm |

Max.dig radius | 5445mm |

The selling points of YC-35U excavator:

1. Engine performance: YC brand excavators are equipped with brand certified engines, ensuring excellent quality and stability worldwide.

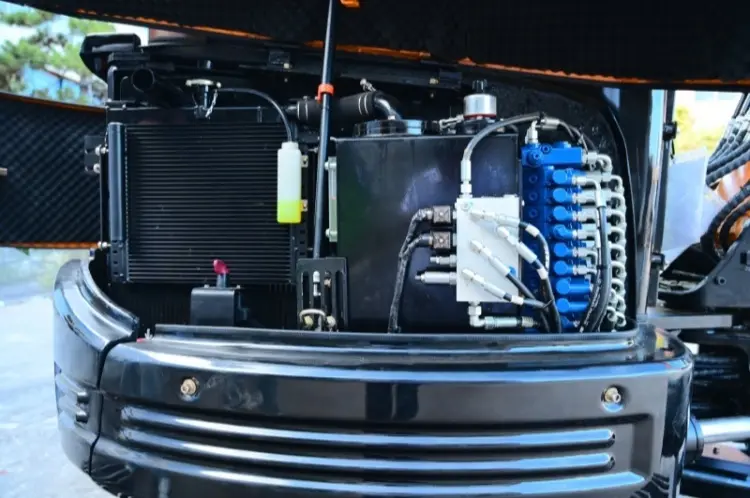

2. Hydraulic system: We use products from industry recognized high-quality pump and valve manufacturers, and customize installation according to customer needs to ensure efficient and reliable operation.

3. Processing technology: Relying on advanced processing technology from large factories, our excavators will perform deep processing after welding the upper and lower plates and the large and small arms. For the parts that require the installation of pins, not only welding treatment will be carried out, but also two opposite holes will be cleaned simultaneously on a large boring machine to ensure that the two holes are concentric, thereby greatly extending the service life of the pins.

4. Material standards: The steel plates used for the excavator bottom plate, swing components, and large and small arms all meet strict weight and quality standards, greatly improving the durability of the equipment.

5. Structural reinforcement: During the welding process of the suspension rod, an internal reinforcement rib design has been added, which can effectively prevent the tearing problem of the suspension rod caused by improper customer operation or heavy load conditions, further improving the safety and reliability of the equipment.

Product details display

Welcome global buyers to visit our factory

The company receives a large number of foreign customers every year to visit and inspect the factory, and repeatedly place new orders. Every time, it leaves a good reputation and impression on customers. From production to quality, as well as the professionalism and cultural literacy of employees, it makes foreigners feel respected!